3D Printer Mits M3DS-SA5

Hotline: +84 906 988 447

Head Office: Ho Chi Minh City

- Tel: +84 2839 778 269 / 3601 6797

- Email: sales@lidinco.com

- Add: 487 Cong Hoa Street, Ward 15, Tan Binh Dist, HCM City, Vietnam

Office: Bac Ninh City

- Tel: +84 222 730 0180

- Email: bn@lidinco.com

- Add: 184 Binh Than Street, Vo Cuong Ward, Bac Ninh City, Vietnam

-

Technical Counseling

100% Free

Technical Counseling

100% Free

-

Free Shipping

For 3.000.000vnd Order

Free Shipping

For 3.000.000vnd Order

Data is being updated

How to read the specification 3D Printer M3DS-SA5

XY resolution and printing size

XY resolution is a size of 1 pixel for the projector. In general, if this value is smaller, smaller feature can be printed more precisely. However, printing size in XY dimensions gets smaller.

Layer thickness and printing speed

Layer thickness is basically fineness of Z direction (height direction), and in general, smaller this value is, surface of the printed object gets finer and smooth. However, overall printing time gets longer

Tray system and coater system

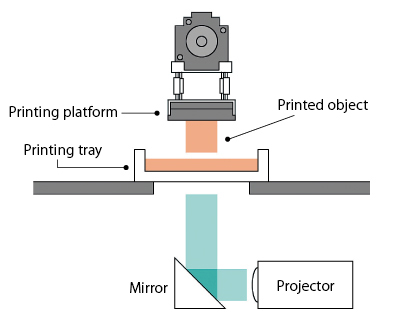

- Tray system

- Putting liquid resin into tray in about 5mm depth, and platform is lifted vertically once while cured, then put down, and this sequence is repeated. When printing soft objects, during lifting and putting into tray, objects shakes a little bit.

- Coater system improved this disadvantage.

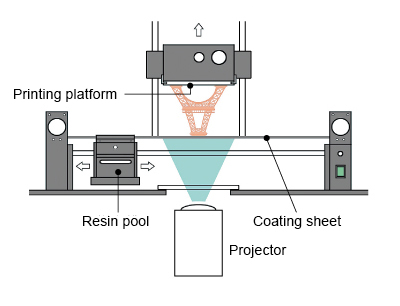

- Coater system

- Before curing, resin for one layer is coated on the coating sheet. The projector radiates image for the layer and the layer is cured. The next step is peeling which the cured resin is peeled off the sheet. Lifting platform, coating resin, curing and peeling. These process is repeated until print is finished. Resin pool is moving left and right during print in order to coat resin and peel off the object.

Vertical lifting and platform submerging

Vertical lifting

FLASH75 and M3DS adopt vertical lifting system. Light is projected through bottom of resin tray for FLASH75, and from under the printing sheet through the sheet for M3DS, the UV light cures 1 layer of resin, and platform is lifted through the process. Printed objects are hung upside-down from platform.

Platform submerging (No MITS 3D printers adopt this type)

Many stereolithographic 3D printers put resin into resin pool at least the depth as deep as the height of the object intended to be printed. Platform will be submerged into the pool through the printing process. UV light is radiated on the surface of the resin to cure. Once the layer is cured, platform sinks down by one layer to form another layer on top of the layer just cured.

Accessories

Please login to write review!