MultiPrep Polishing System – 8″

MultiPrep Polishing System – 8″

- Number Of Workspace:

- Shaft Rotation:

- Diameter Plate:

- Please contact to check stock

- There are currently no promotions for this product

Hotline: +84 906 988 447

Head Office: Ho Chi Minh City

- Tel: +84 2839 778 269 / 3601 6797

- Email: sales@lidinco.com

- Add: 487 Cong Hoa Street, Ward 15, Tan Binh Dist, HCM City, Vietnam

Office: Bac Ninh City

- Tel: +84 222 730 0180

- Email: bn@lidinco.com

- Add: 184 Binh Than Street, Vo Cuong Ward, Bac Ninh City, Vietnam

Technical Counseling 100% Free

Technical Counseling 100% Free Free Shipping For 3.000.000vnd Order

Free Shipping For 3.000.000vnd Order

Data is being updated

Description

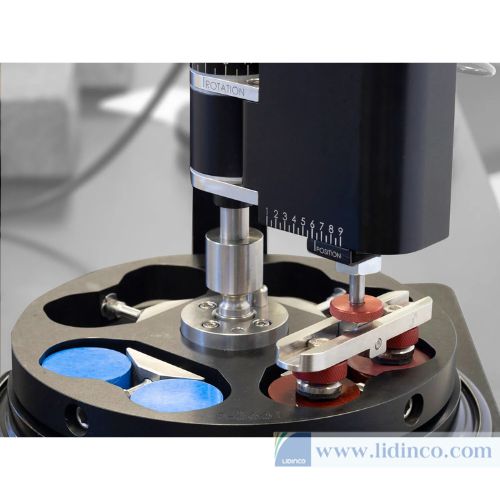

The MultiPrep™ System enables precise semiautomatic sample preparation of a wide range of materials for microscopic (optical, SEM, FIB, TEM, AFM, etc.) evaluation.

Capabilities include parallel polishing, angle polishing, site-specific polishing or any combination thereof. It provides reproducible results by eliminating inconsistencies between users, regardless of their skill.

Dual micrometers (pitch and roll) allow precise sample tilt adjustments relative to the abrasive plane. A rigid Z-indexing spindle maintains the predefined geometric orientation throughout the grinding/polishing process. Digital indicators enable quantifiable material removal, which can be monitored real-time, or preset for unattended operation. Variable speed rotation and oscillation maximize use of the entire grinding/polishing disc and minimize artifacts. Adjustable load control expands its capability to handle a range of small (delicate) to large samples

Features

MultiPrep Positioning Head Features

| Front digital indicator to display real-time material removal (sample advancement), 1 µm resolution | Precision spindle that indexes the sample perpendicular to the platen, and can rotate simultaneously | |

| Dual axis, micrometer controlled angular positioning of the sample (pitch and roll): +10°/-2.5° range (0.02° increments) | Rear digital indicator to display vertical positioning (static) with zeroing function, 1 µm resolution | |

| Full or limited automatic sample rotation with 8 speeds | Cam-locking system that eliminates the need for tools and allows for precise repositioning of fixtures | |

| Variable sample load: 0-600 g (100 g increments) | Designed & manufactured by Allied in the USA |

Grinder/Polisher Features

| Variable platen speed: 5-350 RPM (5 RPM increments) | Digital timer and tachometer | |

| 7″ LCD touchscreen with keypad entry to control all functions | Clockwise/counterclockwise platen rotation | |

| Seamless integration with optional AD-5™ Fluid Dispenser for automatic operation | Electronic coolant control with adjustable valve | |

| 0.5 HP (375 W), high-torque motor | Stable RIM, aluminum and stainless steel construction | |

| Corrosion/impact resistant cover | Two (2) year warranty | |

| Designed & manufactured by Allied in the USA | CE Compliant for EU |

Accessories

- Cam-Lock Adapter for #15-1010, #15-1010-RE, #15-1013

- Cross-Sectioning Paddle with Removable 3.1 mm SEM

- Cross-Sectioning Paddle with Reference Edge for #15-1005, #69-50000, #69-41000, #69-41005

- TEM Wedge/FIB Thinning Paddle with 5.3 mm W x 3.5 mm D (12.7 x 10.2 mm) Pyrex® Insert

- TEM Wedge/FIB Fixture Body and Pk/4 #69-40015 Pyrex® Inserts

- SIMS/TEM Thinning Fixture with 0.5” D x 0.4” H (12.7 x 10.2 mm) Pyrex® insert

- Parallel Polishing Fixture, Stainless Steel, 2.25" (57 mm) Diameter

- Parallel Polishing Fixture, Stainless Steel, 3" (80 mm) Diameter

- Parallel Polishing Fixture, Stainless Steel, 4" (100 mm) Diameter

- Teardrop Fixture 40 mm Mount Capacity

- Weight Kit including: (1) 200 and (1) 100 gram Barrel Weights, (1) 200, (1) 100, and (1) 50 Gram Slotted Weights and (1) Holding Rod

- Multipurpose Fixture, 2" W x 1" H x 0.75" D (51 x 25 x 19 mm) Pocket

- Multipurpose Fixture, 45° Diagonal Orientation, 2" W x 1" H x 0.80" D (51 x 25 x 20 mm) Pocket

- Multipurpose Fixture, 1.00" W x 0.40" H x 0.45" D (25 x 19 x 11 mm) Pocket

- Multipurpose Fixture, 45° Diagonal Orientation, 1.0" W x 0.4" H x 0.5" D (51 x 10.2 x 12.7 mm) Pocket

- Cross-Sectioning Paddle, Clamp Style with 0.63" W x 0.10" H x 0.25" D (16 x 2.5 x 6.4 mm) Pocket

- Cross-Sectioning Paddle, Clamp Style, Diagonal Orientation with 0.63" W x 0.10" H x 0.25" D (16 x 2.5 x 6.4 mm) Pocket

- Digital Indicator Measurement System, with Granite Stand

- Precision Aluminum Platen, 8" (203 mm)

- Precision Magnetic Platen, 8" (203 mm)

- Platen Storage Cabinet for Platens, Discs or Cloths up to 12" (305 mm) Diameter

- Aluminum Tray/Shelf

Please login to write review!