MultiPrep Polishing System – 12″

MultiPrep Polishing System – 12″

- Number Of Workspace:

- Shaft Rotation:

- Diameter Plate:

- Please contact to check stock

- There are currently no promotions for this product

Hotline: +84 906 988 447

Head Office: Ho Chi Minh City

- Tel: +84 2839 778 269 / 3601 6797

- Email: sales@lidinco.com

- Add: 487 Cong Hoa Street, Ward 15, Tan Binh Dist, HCM City, Vietnam

Office: Bac Ninh City

- Tel: +84 222 730 0180

- Email: bn@lidinco.com

- Add: 184 Binh Than Street, Vo Cuong Ward, Bac Ninh City, Vietnam

Technical Counseling 100% Free

Technical Counseling 100% Free Free Shipping For 3.000.000vnd Order

Free Shipping For 3.000.000vnd Order

Data is being updated

Description

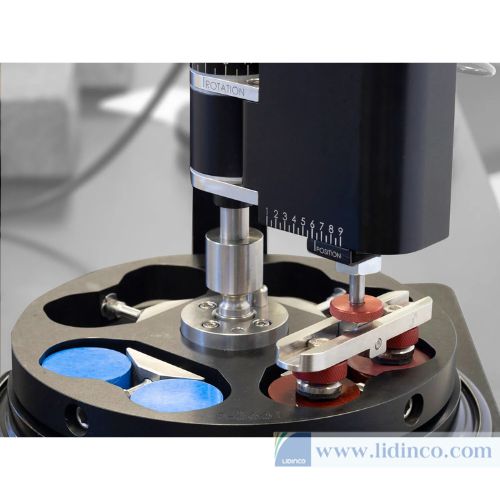

The MultiPrep™ System enables precise semiautomatic sample preparation of a wide range of materials for microscopic (optical, SEM, FIB, TEM, AFM, etc.) evaluation. Capabilities include parallel polishing, angle polishing, site-specific polishing, or any combination thereof. It provides reproducible results by eliminating inconsistencies between users, regardless of their skill. The 12" MultiPrep™ System has a scaled positioning device and higher torque rotation/oscillation motors for preparation of larger or multiple samples exceeding an area of 1,600 mm².

Dual micrometers (pitch and roll) allow precise sample tilt adjustments relative to the abrasive plane. A rigid Z-indexing spindle maintains the predefined geometric orientation throughout the grinding/polishing process. Digital indicators enable quantifiable material removal, which can be monitored real-time, or preset for unattended operation. Variable speed rotation and oscillation maximize use of the entire grinding/polishing disc and minimize artifacts. Adjustable load control expands its capability to handle a range of small (delicate) to large samples.

Features

MultiPrep Positioning Head Features

| Front digital indicator to display real-time material removal (sample advancement), 1 µm resolution | Precision spindle that indexes the sample perpendicular to the platen, and can rotate simultaneously | |

| Dual axis, micrometer controlled angular positioning of the sample (pitch and roll): +10°/-2.5° range (0.02° increments) | Rear digital indicator to display vertical positioning (static) with zeroing function, 1 µm resolution | |

| Full or limited automatic sample rotation with 8 speeds | Cam-locking system that eliminates the need for tools and allows for precise repositioning of fixtures | |

| Variable sample load: 0-600 g (100 g increments) | Designed & manufactured by Allied in the USA |

Grinder/Polisher Features

| Variable platen speed: 5-350 RPM (5 RPM increments) | Digital timer and tachometer | |

| Touchpad switches control all functions | Clockwise/counterclockwise platen rotation | |

| Seamless integration with optional AD-5™ Fluid Dispenser for automatic operation | Electronic coolant control with adjustable valve | |

| 0.5 HP (375 W), high-torque motor | Stable RIM, aluminum and stainless steel construction | |

| Corrosion/impact resistant cover | Two (2) year warranty | |

| Designed & manufactured by Allied in the USA | CE Compliant for EU |

Accessories

- Splash Ring & Platen Cover

- Dial Indicator Calibration Kit

- Fixture/Accessory Storage Case

Please login to write review!